1D NEED TO KNOW Plastic and Waste Management

Top Tip: Before you carry out the audit, it is important to understand the different types of plastic that exist and their associated impacts.

Understanding plastics, bioplastics and recycling terms

Many types of plastic are non-recyclable, so they go to incineration, landfill, chemical or mechanical recycling. No fossil fuel based plastic will fully compost or biodegrade. It will only break up in to smaller and smaller pieces (microplastics - nanoplastics etc).

Bioplastics can be partly fossil-fuel based or created entirely from other materials. If they contain fossil fuels they will never fully disintegrate. If they are made from other materials they may biodegrade but it could take several years. This means these can cause the same harmful effects to the environment or creatures as plastic.

There are different types of solutions, but to ensure they are effective it is essential to understand how they are processed at the point of disposal. These terms can be real – or they can be buzzwords to sell a product. Research each item carefully and how it should be disposed of.

TERMS USED FOR TYPES OF PLASTIC

Here are some important phrases to understand. These should be shared with the school community. Can you find others to add to the list?

· Biobased

· Biodegradable

· Degradable

· Decomposable

· Compostable

· Marine Degradable

· Environmentally friendly

· Oxybiodegradable

· PLA (Polylactic Acid)

· Cellulose

Sustainable Alternatives

Recently several companies and individuals have been energised to take action to address plastic pollution. This is a great renaissance.

However, it is worth understanding this is an ongoing process and some solutions must be considered short

term while others may encounter negative environmental

effects later down the line. Be ready to go back to the drawing board with an open mind and new solutions. Everyone is trying and some efforts may prove successful in the long run, but others will not.

Bioplastics

Bioplastics (or biobased plastics) are plastic-like substances that are made from renewable materials, such as corn, wheat, potato, coconut, wood, shrimp shells, etc. But only a small portion of the plastic may be renewable.

Polylactide acid (PLA) can have the same properties as plastic and can be made with far less energy.

To be called a bioplastic, a material only needs 20 percent of renewable material; the other 80 percent could be fossil fuel-based plastic resins and synthetic additives meaning that when they are composted, they can leave toxic residues or plastic components behind, and harm the soil.

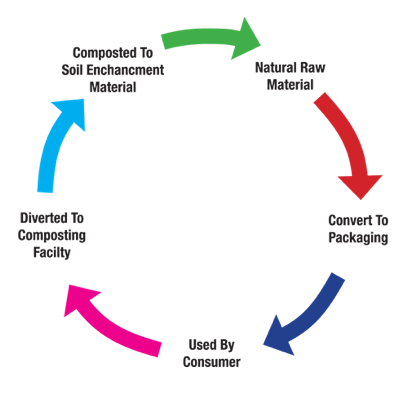

Compostable

Compostable refers to an item that will break down in industrial and (sometimes) home composting systems. It should biodegrade to natural elements leaving no toxicity in the soil. This typically will occur in about 90 days (although lengths of time vary). It is important to check if the product meets “home compostable” standards - or if it requires industrial composting facilities and are these even available?

Home compostable plastics (like wood pulp cellulose) will biodegrade In a home compost in a temperature range of 20-30 degrees centigrade.

Bioplastic is rarely home compostable. For example, it may require “industrial composting” at a special facility with temperatures of 60+ degrees centigrade - separate from normal organic waste.

Oxybiodegradable

· These are traditional fossil fuel-based plastics but combined with transition metals (cobalt, manganese, and iron) to cause the plastic to break up Into small pieces when triggered by UV radiation or heat. The additives make the plastic break up faster - but it never completely degrades

· Therefore, caution is required to determine exactly what type of plastic or bioplastic is being used and where the waste is going and how it is being treated.

Both “biodegradable” or “compostable” items may have to be composted in an industrial composting facility - and separated from normal organic waste compost.

Problems with plastics and bioplastics

· Maize-based bioplastics mean land for growing food is instead being diverted to “plastic-growing”, which could create problems further down the line.

· Most waste management facilities do not have the equipment needed to process biodegradable plastic properly. Check in your area first

|

|

Trash |

Recycle |

Home Compost |

Industrial |

|

Bioplastic |

Likely |

No |

Not Llikely |

Perhaps |

|

Biobased Plastic |

Likely |

No |

No |

Perhaps |

|

PLA |

No |

No |

No |

Yes |

|

Compostable |

No |

No |

Perhaps |

Perhaps |

|

Home Compostable |

No |

No |

Yes |

No |

|

Industrial Compostable |

No |

No |

No |

Yes |

|

Biodegradable |

No |

No |

Perhaps |

Perhaps |

|

Oxybiodegradable |

Yes |

No |

No |

No |

· Both biodegradable and bioplastics are also difficult to recycle. PLA intentionally looks very similar to PET, meaning that the two are often mixed in the same recycling bin, meaning that recycling collection can be comprised.

· Bamboo is often pulped and mixed with formaldehyde to create reusable plates.

· Depending on how long bioplastics take to biodegrade, they can still cause harm to living creatures until they decompose. If a piece of biodegradable plastic ends in the ocean, it could still end up in the stomach of a seabird or around the neck of a turtle for long enough to cause injury or death.

Therefore, if the school does not have a commercial composting facility nearby, other solutions to single use plastics should be considered.

Err on the side of caution and place in trash if in doubt.

Badly recycled goods can contaminate the entire recycling shipment. Better to research these products and how they can be disposed of in your area before seeking them as a substitute - each area has different criteria of what It will accept so research this carefully first.

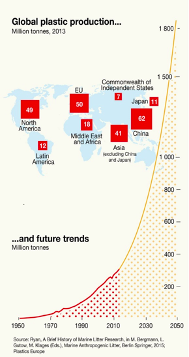

WASTE MANAGEMENT

The disposal of plastic waste has long been one of 'passing the buck' – until recently most plastic waste was shipped to China or other countries for "recycling". (Most of this was incinerated or buried in landfills) This practice was stopped by China In 2018 and the rest of the world had to look at It’s the plastic waste It generated.

It is a tough problem the best solution is to STOP producing more plastic and either reuse what we have or find a more sustainable solution.

Top Tip: What do you think this symbol means?

Do you think it means that this is automatically recyclable?

Did you know that this is actually just an indicator of the type of plastic?

In this case “2” means HDPE or High-Density Polyethylene.

This does not mean that this item can actually be recycled where you are.

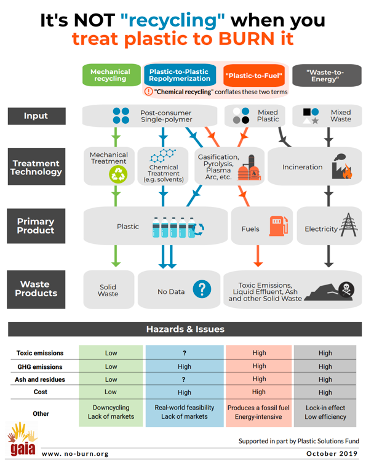

Recycling

Recycling is a complicated and sometimes imperfect process of converting waste materials into new materials. This process allows us to reduce the production of raw materials and limit energy usage and pollution. While recycling can be very useful, it has often been falsely heralded as the solution to plastic pollution, it is not that simple. Recycling is a hugely energy-intensive process and can still be very polluting.

Furthermore, plastic products have a huge variety in composition, colour, weight and size – so they cannot be recycled together. For example, coloured plastics are very difficult to recycle so Materials Recovery Facilities (MRFs) gain little market value for their efforts.

- Plastic recycling also has many barriers to its feasibility: firstly, if recycling is improperly sorted by the consumer, it can contaminate different types of waste, so they cannot be recycled.

- Secondly, plastic recycling is very local-specific: if a certain type of plastic is not accepted by a local municipal recycling program, it can mean that MRFs are over-saturated by receiving plastics they cannot process.

- Because recycling relies on:

a) collection points

b) pick up and transportation points

c) processing points

and these are mostly based on local taxes and market prices - the frequency and profitability of recycling can vary greatly -

Plastics the Facts 2019 Europe

For example:

- 19% of plastic reported as “recycled” is treated outside the EU

- incineration has risen by 77% from 2006

- landfill restrictions do not encourage recycling

Mechanical Reycling

For recyclable plastic types, like PET, the process is not ideal: in some processes they can only be recycled once or twice before the chemical properties have been too damaged to be recycled again. Often up to 30% virgin plastic must be added to recycled plastic pellets to be useable. In addition, it uses more energy and releases more greenhouse gas emissions to produce.

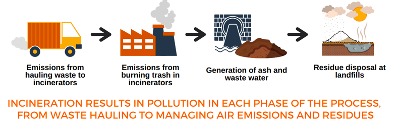

Incinerator

An incinerator burns waste which creates steam that is used to drive turbine-generators to produce electricity. This process is known as incineration or waste-to-energy (WTE). Nearly a quarter of all municipal solid waste is burned in incinerators in Europe, and this treatment is becoming increasingly popular worldwide. For countries lacking landfill space, incineration is considered a bulletproof solution.

WTE incineration is often falsely labelled as recycling and considered a green solution for waste management. However, producing goods from virgin, finite resources requires a significant amount of energy, and burning them in an incinerator destroys those resources for good and releases more greenhouse gas emissions.

If plastics are incinerated - they leave toxic residue - for each 100kg of waste that Is burned, about 20% remains as toxic sludge/slurry that must be dealt with. This quickly adds up to more concentrated waste.

Finally, if all plastic production were to stop today, and because of all plastic ever produced, half of it has been produced in the last 13 years, AND only 9% of all plastics have EVER been recycled - there is still a huge backlog of plastics in circulation.

Add to this that plastics producers are planning on tripling their plastic production and the mathematics do not look hopeful - unless we prevent plastic waste in the first place, re-use and recycling as a last resort..